Dongguan ManRoland Precision Machinery Co., Ltd

Contact: Mr. Jiang

Tel: 13920993307

Contact: Mr. Zhou

Tel: 18038205092

Address: No. 8, Hongye street, Xixi village, Liaobu Town, Dongguan City, Guangdong Province

Website: en.dgmll.net

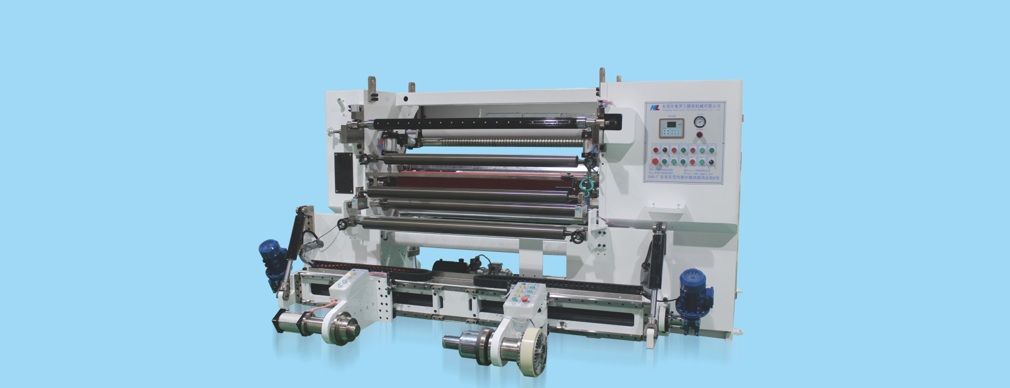

Optical film Slitter mgx-1350

This machine is suitable for:Optical film, release film,PET, OPP, CPP, PVC, paper andso on.

●Uncoiling adopts shaftless uncoiling: the uncoiling mechanism adopts hydraulic shaftless center type uncoiling, the uncoiling arm can be

adjusted up and down and left and right, the maximum load is 2000kg, and a set of3 "6" inch taper plugs is provided. Even under full load, the operator can easily complete the coiling operation by simply operating keys, greatly reducing labor intensity, reducing coiling time and improving production efficiency.

●AC ultrasonic system is used to rectify the deviation. Ultrasonic wave detects the edge of the material and automatically identifies the material without any adjustment. AC motor is used to drive the material. It is sensitive and accurate in response and tracking.

●Humanized control of the whole machine, 10-inch touch screen man-machine interface, Mitsubishi PLC centralized control, switch keys,adjustment handle, logo, color design in line with the requirements of ergonomics and national safety and quality inspection standards, digitaldisplay, frequency conversion speed regulation, intelligent fixed-length stop, emergency stop, overload protection and other functions.

The machine is controlled by three motors, and the material receiving shaft is slippery shaft, which is easy to be replaced and maintain.

S/N | Name | Specification |

1 | Slicing thickness | Protective film 0.025-0.5MM |

2 | Raw material width | 1301300mm (wheel face width 1400mm) |

3 | Maximum unwinding diameter | Φ900 mm(effective width of unwinding 1350mm*width of paper tube) |

4 | Maximum take-up diameter | Φ600Mm-Up and Down Double Axis |

5 | Minimum Split widt | 30 mm - 1300mm |

6 | Uniformity of cut end face | 0.1 mm (accuracy of士0. 15 with straight knife) |

7 | Inside diameter of take-up die | 3 "(76.2 mm) slip shaft |

8 | Mechanical running speed | 0-220 M/min (design speed, only due to material characteristics) |

9 | Power Supply | 380V 50HZ |

10 | Total machine power | 25KW |

11 | Mechanical dimensions approx | Length 3800mm*Width 2700 mm*Height 1700mm |

12 | Splitting mode | Circular knife cutting, straight knife sharing type |

13 | Discharge frame | Shaftless feeding |

14 | Unwinding tension detection | Automatic Adjustment of Constant Tension Real-time Detection |

15 | Edge treatment | straight Blow 1.1 KW + Sidewinder directly with a fan to reel |

16 | Discharge | Take-up shaft discharge rack discharge |

17 | Reeling roller | Wheel-type pressing roller for removing air bubbles |

18 | Protective film release reel | 3 "(76.2 mm) Inflatable shaft, using pendulum to unload and load materials, without unloading shaft, reducing labor intensity, magnetic powder discharging, manually adjusting the opposite side, discharging film diameter 350 |

Address: No. 8, Hongye street, Xixi village, Liaobu Town, Dongguan City, Guangdong Province Tel: 18038205092 / Mr. Zhou